● Free from its forms

Characteristics of MEC's Induction Bending

- MEC’s induction bending doesn’t use any former or mandrel, bending radius and angle is easy to be changed, and various form of bends having single, double and three dimensions can be manufactured without problem.

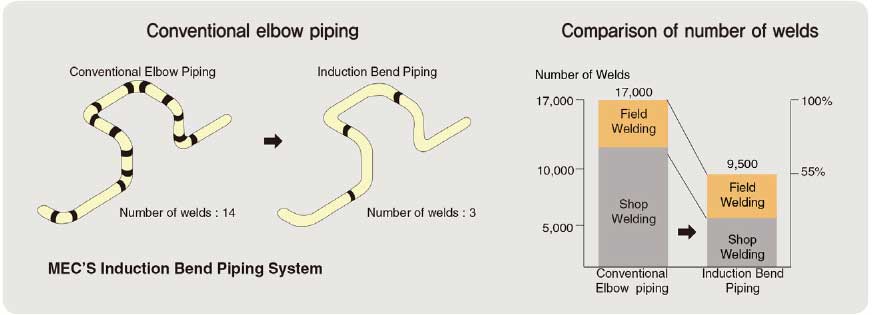

● Construction costs saving

- MEC’s high-frequency bending can be considered as pipes with elbows already attached, which can significantly reduce the number of welding joints. This can lead to shorter inspection and construction times, resulting in overall cost savings in construction.

● High quality

- MEC’s induction bending is implemented with a compression bending mechanism, so the reduction and ovality are smaller than those of other conventional bending methods.

● Freedom of design

- MEC’s high-frequency bending is produced in a variety of angles, shapes, and arbitrary bending radii, making it possible to design more freely than welded elbows produced in limited angles (45° or 90°).

● Scope of induction bending

| Material | Carbon steel, Alloy steel. Stainless steel, Aluminum, Titanium, Hastelloy, etc. | Size | Min. 2"(50A) ~ Max. 24"(600A) |

|---|---|---|---|

| Wall thickness | Maximum 50mm | ||

| Standard | API, ASTM. JIS, ISO, BS, etc. | Bending radius | 1.5DR, 2DR, 3DR~ Max. 15,000mm |