MJ TSR, leading the high-technologies with more efforts than the others, consistently innovates itself for the new values to meet our customers expectation. Our MPEL PIPES which gain public favor in various industrial fields such as shipbuilding, power plants, and petro-chemistry, support customers’ success with the best quality and punctual delivery.

We realize world class quality through constant

Research and innovations

● Characteristices of MPEL PIPE

- Excellent Corrosion Resistance

- Excellent Adhesive Strength

- Excellent Abrasion Resistance

● Applications

- Chemical Industry

- Power Industry

- Extracting Industry

- Steel Industry

- Food Industry

- Petrochemical Industry

- Metal Industry

- Pharmaceutical Industry

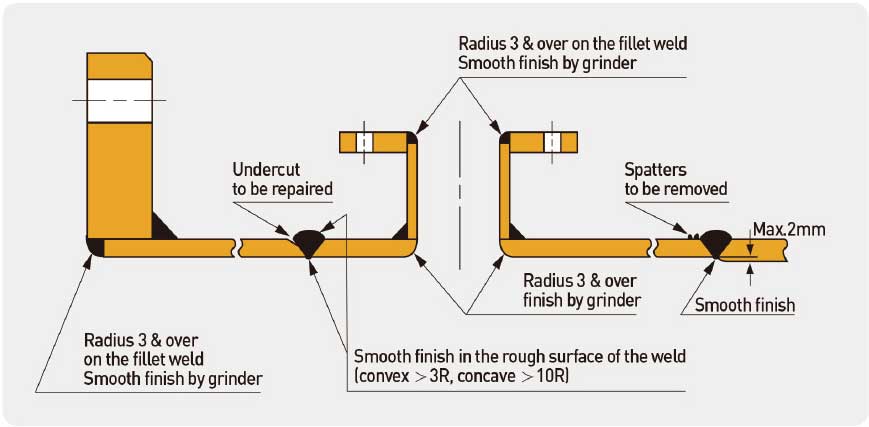

● Pipe Prefabrication Standard for Lining

When preparing the piping component for rubber or polyethyene lining,

please pay attention to the following to get the best quality of lining.

- The surface of piping component to be lined should be cleansed of oil, grease, paints, zinc coatings, etc.

- The sharp edges and corners of piping component should be finished by grinding more than 3R

- The concave surface damaged or pitted by rust should be smoothly grinded more than 10R

- The welding defects such as backbead projection, spatters, undercut, blowhole, etc. should all be removed.

- The internal misalignment of the ends to be joined shall not exceed 2mm or be trimmed according to the right figures.