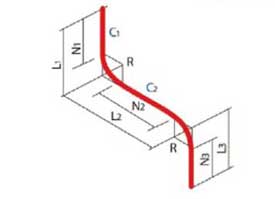

● Minimum Tangent Length for Induction Bending

Technical Information for Induction Bending

| NOM. DIA. | O.D | R/D(Min) | Radius | Clamp Length | ||

|---|---|---|---|---|---|---|

| C1 | C2(+) | C2(-) | ||||

| 100 | 114.3 | 1.5 | 171 | 280 | 280 | 450 |

| 125 | 139.8 | 1.5 | 210 | 320 | 320 | " |

| 150 | 165.2 | 1.5 | 248 | 360 | 360 | " |

| 200 | 216.3 | 1.5 | 324 | " | 380 | " |

| 250 | 267.4 | 1.5 | 401 | " | 380 | " |

| 300 | 318.5 | 1.5 | 478 | 480 | 460 | 550 |

| 350 | 355.6 | 2 | 711 | 510 | " | " |

| 400 | 406.4 | 2 | 813 | 530 | 550 | " |

| 450 | 457.2 | 2 | 914 | 630 | 650 | " |

| 500 | 508 | 2 | 1016 | " | " | " |

| 550 | 558.8 | 2 | 1118 | " | " | " |

| 600 | 609.6 | 2 | 1219 | " | " | " |

| - | - | - | - | Type-A | Type-B | Type-C |

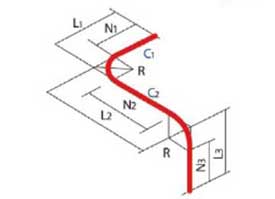

Type-A

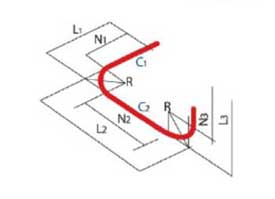

Type-B

Type-C